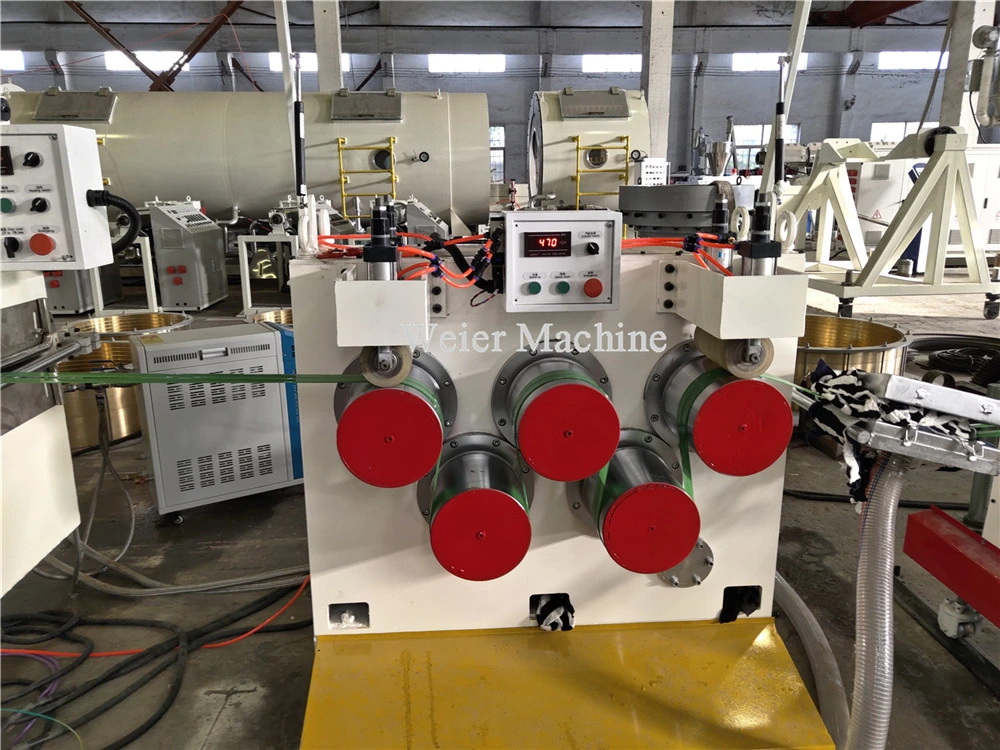

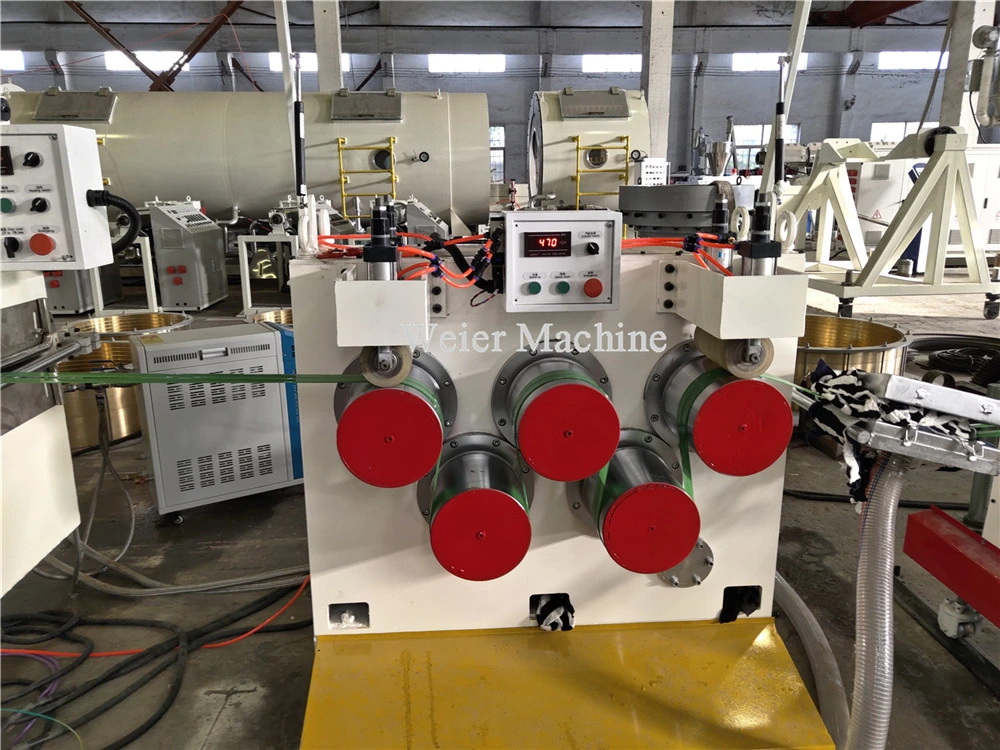

PET strap production machine /strap making machine/PET strapping extruder

- PP strap band extrusion line is mainly for producing PP strap.

- The raw material can be 100% recycled material, which can reduce the Pproduce cost and get a good profit.

- And The PP bale is the substitution of the steel strap and has a lot of advantages such as good extension,

- high temperature resistant, easy use.

- It is mainly suitable for packaging for various trades.

Advantages of PET strap production machine /strap making machine/PET strapping extruder

The use of PP strap band is convenient and it can adopt common steel fastening for connection. It also is suitable

for various kinds of hand-operated of table packing machine and large auto-packaging machine of enterprises

for various kinds of hand-operated of table packing machine and large auto-packaging machine of enterprises

PET strap band production line model

| Model | SJ-65 | SJ-75 | SJ-90 |

| Extruder | SJ-65/28 | SJ-75/30 | SJ-90/30 |

| Productivity | 60-100kg/h | 80-120kg/h | 200kg/h |

| Drive Motor | 22kw | 30kw | 75kw |

| Two-station Winder | 80-120m/min,adjustable | ||

| Strap Size | Width:5mm-20mm | Width:10mm-25mm | Width:20mm-35mm |

| Thickness:0.36mm-1.0mm | Thickness:0.5mm-1.3mm | Thickness:0.5mm-1.8mm | |

| Installed Capacity | about40kw | about 60kw | about80kw |

| Line Dimension | 26m×2m×2.2m (L×W×H) | 26m×3m×3m (L×W×H) | 26m×5m×3.5m (L×W×H) |